how to measure gold plating thickness|gold plating thickness chart : import Microns measure the thickness of gold plating: 1 micron: 0.001 of a millimetre Heavy gold plated: 2.5 microns and up (if on silver, also called vermeil, but more on this later) Resultado da Watch free most popular movies and TV shows online in HD on any device. Tubi offers streaming most popular movies and tv you will love.

{plog:ftitle_list}

WEBVind penge i konkurrencer. Her finder du spil og konkurrencer hvor du kan vinde penge gratis. Hvem kan ikke bruge lidt ekstra penge? Pengepræmier er altid populære i .

Because specifications play a key role in determining pricing, quality and durability of plated finishes, it is important to clearly understand the definitions, particularly when measuring layer thickness on gold plated .

To measure the thickness of gold plating, specialists use precise tools. Here are some popular methods: X-Ray Fluorescence (XRF) Spectrometry: Non-destructive and accurate. Electronic Thickness Testers or Digital Micrometers: . In decorative gold plating, a minimum thickness should be achieved with little excess to ensure that the expensive, precious metal is not .Microns measure the thickness of gold plating: 1 micron: 0.001 of a millimetre Heavy gold plated: 2.5 microns and up (if on silver, also called vermeil, but more on this later) The thickness of the gold layer is typically measured in units called microns. A typical range for gold plating thickness is between 0.5 to 2.5 microns. Jewelry with a gold layer of less than 1 micron will often wear out .

Typically, gold plating is measured in microns, with common thicknesses ranging from 0.5 to 5 microns. A higher gold content in this layer means better corrosion resistance and a longer . Bob Willis videos show you How to Do It each month. This month we talk about plating thickness measurement. The correct plating quality and thickness can be .

How is the thickness of gold plating measured? The thickness for gold coatings and platings are often expressed in millionths of an inch, microinches, or microns. The table below will help .The best way to measure and verify the thickness of a heavy build up plated layer is by using a combination of X-Ray Fluorescence (XRF) and Eddy Current Testing (ECT). XRF is a .

Plating thickness measurements are important because a coating’s durability depends on the coating’s thickness. Thicker coatings provide more protection, whereas thinner or uneven coatings leave the material exposed to corrosion, .

Thickness distribution on the part can vary from 5-15% depending on the variables mentioned here. The method is also time consuming and labor intensive. UPA Technology has gold thickness measurement devices if you don't currently have one. Using one will save you a lot of time and money, and help you keep your gold thickness distribution in check.atomic number of the coating layer, and the energy of the emitted lines used. In the past, XRF has been used to measure coat-ing thickness using stationary or benchtop instru-ments. However, the specimen must be brought inside or close to the analyzer chamber for analysis using stationary XRF methods, making measuring coating thickness on large .XRF coating thickness measurement is a necessity for the billion metal finishing industry. It is also the technology tool that allows contract platers, whose margins are always under pressure, to deliver high quality coatings at lowest cost, knowing they are avoiding the risk of producing below spec, and the cost of wasting valuable material.

SGS MSi can perform plating thickness testing using SEM and optical microscopy and testing to ASTM B748, B747, E3-11 and A90. . Gold; Nickel; Copper; Chromium; Chro; Cadmium ; . ASTM A90 Coating Weight Determination. ASTM A90, is the analytical method for measuring the amount of zinc coating applied to a steel product for a specified .An electroless nickel coating is uniform; it will not build up on corners or projections. The deposited metal layer has an even thickness over all surfaces of the component regardless of its shape; this cannot be achieved with electrodeposited coatings. Typical thickness of electroless plating can be as thin as .0005" and up to.010". This is especially true if the point of thickness measurement is at the end of the part or on the inner diameter. In these cases, choosing the correct point of measurement (POM) is critical. . We specialize in plating of gold, silver, rhodium, palladium, nickel and tin-lead using a variety of techniques including barrel, reel-to-reel .Measuring Plating Thickness . Plating used on electrical component leads and as printed-wiring-board finishes is usually thin, less than 300 micro-inches, and it is important to verify that the plating thickness meets specifications. . Gold plating thickness over nickel or nickel-phosphorus alloy can also be determined by SEM Lab, Inc. using .

The items subsequently have a precious metal coating applied to them (silver or gold) which tend to increase the visual aesthetics of the component but keep the manufacturing costs low. The cost benefits can then be passed to the consumers. . Although an easy to use and highly versatile method for coating thickness measurement, the sample can .Plating, the process of covering a substrate with a thin layer of metal, plays an essential role in modern manufacturing and materials science. The thickness of the plating layer is a critical parameter that can significantly impact the finished product’s performance, durability, and aesthetic qualities. In industries where precision is non-negotiable, such as aerospace, .cycles, reducing agents, and equipment. In addition, electroless plating provides uniform thickness and deposits, especially in deep recesses, bores, and blind holes. Alternative plating methods such as PVD, CVD, and thermal spraying reduce the amount of contaminated wastewater produced by plating, but have high unit-plating costs. 3.0 COATING . The Vanta handheld XRF analyzer can measure coating thickness from 0.00 to approximately 60.00 microns, depending on the material. X-rays are emitted from the analyzer, and they strike the sample, causing it to fluoresce. The analyzer detects the returning X-rays and uses the data to calculate the thickness of the coating or coatings.

The plating thickness measurement is an important part of the electroplating process quality inspection and an important guarantee for the quality of the electroplating products. In order to control the plating thickness, various measurement methods are needed. The most common of which is the non-destructive measurement of the plating thickness . A thicker layer means more gold has been used, which can result in a more durable and longer-lasting finish. The thickness of the gold layer is typically measured in units called microns. A typical range for gold plating thickness is between 0.5 to 2.5 microns. Jewelry with a gold layer of less than 1 micron will often wear out quickly, leading .

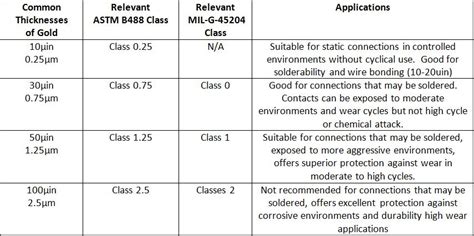

How does Metal Arts Specialties measure gold plating thickness? For applications where plating thickness is critical we periodically measure plated layers using a process called ” x-ray fluorescence”. This non-destructive method is very precise for measuring the actual metal deposition on an object after electroplating. How Thick Should The Gold Plating Be? The thickness of the gold layer will depend on the application of the gold-plated piece. For example, a thin gold coating (0.1 – 0.3 microns) is often used in low-contact applications, . Eddy current coating thickness gages (e.g. PosiTector 6000 N Series) look and operate like electronic magnetic gages. They are used to measure paint and coating thickness over all nonferrous metals. Like .Here’s a look at gold plating thickness standards for connectors so that you’re able to design gold plating at the minimum thickness for performance and cost savings. Gold Plating Thickness for MIL-DTL-45204D and ASTM B488. MIL-DTL-45204D, as you likely know, is a technical military specification for gold plating.

Gold Plating Thickness Guidelines. Use the following gold electroplating thickness breakdown to help you determine the best level for your manufacturing applications: Thin: A thin gold coating in the 4uin to 0uin range will work well for low-contact applications or when you require excellent solderability. Consider this level when using .

what is heavy gold electroplate

Determining PCB gold plating thickness is a quality control measure in the production of hard gold PCB. Conclusion. As we can see, most electronic devices contain gold. Gold is a precious metal with great properties. Gold plated circuit boards are one of the most common boards in the electronic industry. These boards are ideal for use in most . A. Hi Dinesh, You may measure the thickness as Ted said. Usually for plating precious metals like gold, platinum, Palladium, Rhodium etc. it is always good to know the wt. in mg deposited on 1 dm square, for one micron.

Verification Process and Standards in Measuring Plating Thickness. Verification process and standards are important in measuring plating thickness accurately. The verification process is used to make sure that the measurements taken with the plating thickness measuring device are accurate and meet the standards set by the industry.Permanent Magnet Coating Thickness Gauges. A permanent magnet is mounted on a balanced arm and the force required to pull this magnet from the surface of the coating is a measure of the thickness of the coating. Force is applied through a helical spring attached to the balanced arm at one end and to a scale wheel at the other. The plating thickness can be controlled by adjusting the immersion time in the plating tank. Step 8: Final Rinse. . simple, nondestructive solutions for gold analysis. You can measure the content of all gold and precious metals, as well as determine the presence and concentration of other trace, alloying elements, and dangerous heavy elements .

Measuring Gold Plating Thickness. When you wear gold plated jewelry, you might wonder just how much gold is actually covering the piece. The thickness of gold plating is an important aspect of its quality and value. Measuring it accurately can tell you a lot about the piece’s durability and overall worth. This post will explain how to measure .

Besides, it also includes thickness measurement. Conclusion. We can see that gold is such a precious metal and has its importance in the electronics industry. It is one of the commonly used surface finishes in PCBs. . It includes specifications for gold plating thickness, adhesion, and other relevant characteristics. MIL-PRF-55110G. If the gold coating thickness increases, the backscatter rate increases. The change in the rate of electrons reflected is, therefore, a measure of the coating thickness. The test specimen has to be placed on an aperture, so that a defined surface area is exposed to the electron radiation.

MIT Folding Tester vendor

Cotas Minas Tênis Clube. Compre ou venda sua cota agora do Minas Tênis Clube. Ver planos Entrar em Contato. Previous Next. Sobre nós A mais de 10 anos no mercado comprando e vendendo a sua cota com segurança, toda transação feita dentro da secretaria do clube para a segurança do cliente , o melhor clube de Belo Horizonte, .

how to measure gold plating thickness|gold plating thickness chart